experiments

As some readers know, my most recent printworks have been utilizing an inkjet printed clear mylar layer over a print on paper. I’ve expressed some dissatisfaction with the mylar’s shine and reflection. So, I’ve been looking into alternative materials for new work in the same series, and found some sheer polyester organza which I’ve been experimenting with. The fabric is very light and hard to cut square and obviously had to be attached to some support in order to feed it through the wide-format printer. I’ve done several tests:

1. I sprayed repositionable adhesive on fairly sturdy paper. Unfortunately the can was old and the glue sputtered on unevenly. It was difficult to get the sheer cloth on evenly and I got a lot of glue on my fingers. (Use gloves next time!) At the printer, I had a bit of difficulty feeding it in as it has to wrap around the feeding roll, but it did print! RESULT: Most of the ink passed through to the backing paper. Glue bits were stuck on the organza even after lifting it off the paper.

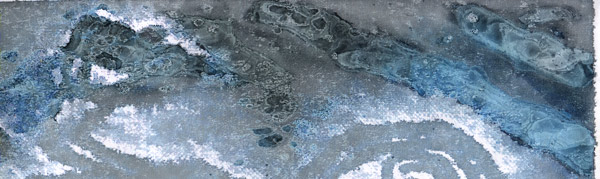

2. A fellow artist offered his poly-coated freezer paper to try out. I ironed the organza to this. To assure the edges stayed stuck I used painters’ green tape over the edges of the organza, gradated to the edge of the freezer paper. This went through the press quite well. RESULT: Like #1, more ink ended up on the backing, but because the coating is non-absorbent the ink pooled in some areas, so I let the ink dry before peeling the fabric off. The printed freezer paper looks pretty interesting, and the blotchy spots did remain on the fabric though faintly.

3. I tried to repeat #2 but this time the paper jammed in the printer heads, because it curls upwards! We do not want to damage the printer-heads!

4. This time I took the freezer paper/organza and taped it to a lightweight art paper. The printer heads did drag over some of the tape.

5. Repeated # 4 using thin transparent tape. This caught on the printer heads too!

CONCLUSION: The freezer paper coating is not strong enough to hold down the cloth against the handling over the feed roller and the vacuum, hence causing the fabric to lift at the tape edges and catch in the printer heads. Goodbye to this technique.

NEXT TESTS: Back to #1 with a fresh new can of repositionable adhesive and using a lighter paper backing. In addition, inkjet vellum is now on order and we’ll see how that works.

I really have to think some more about how to successfully incorporate the image on the organza because it is rather faint. I’ve also been wondering if the polyester fibre is the right choice, silk likely would have been preferable but the store did not have this. I’ve even had a bit of a “chat” with Omega, a new virtual friend and fabric-artist blogger of the fascinating Threading thoughts, who has confirmed this in her own practice.

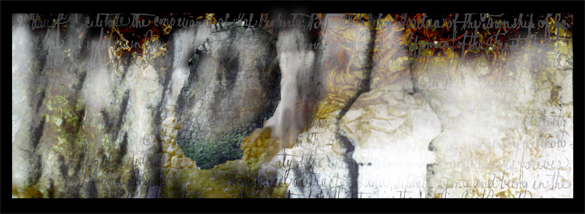

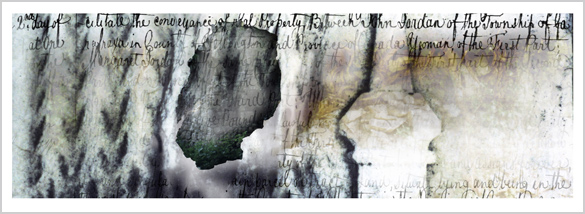

The above image is an interesting detail of one of the test prints left behind on the freezer paper. (Someone pointed out that this is an inkjet silkscreen print!)

ADDENDUM March 2nd, 2006: Continued in experiments, part 2